3D Printing Services: Transforming Ideas into Reality Quickly and Efficiently

The evolution of 3D printing services has transformed industries by offering innovative solutions to design and manufacturing challenges. These services enable businesses to leverage additive manufacturing for rapid prototyping and the creation of custom parts, streamlining the production process and reducing material waste. As technology advances, the possibilities for customization and creativity expand, making 3D printing an attractive option for businesses of all sizes.

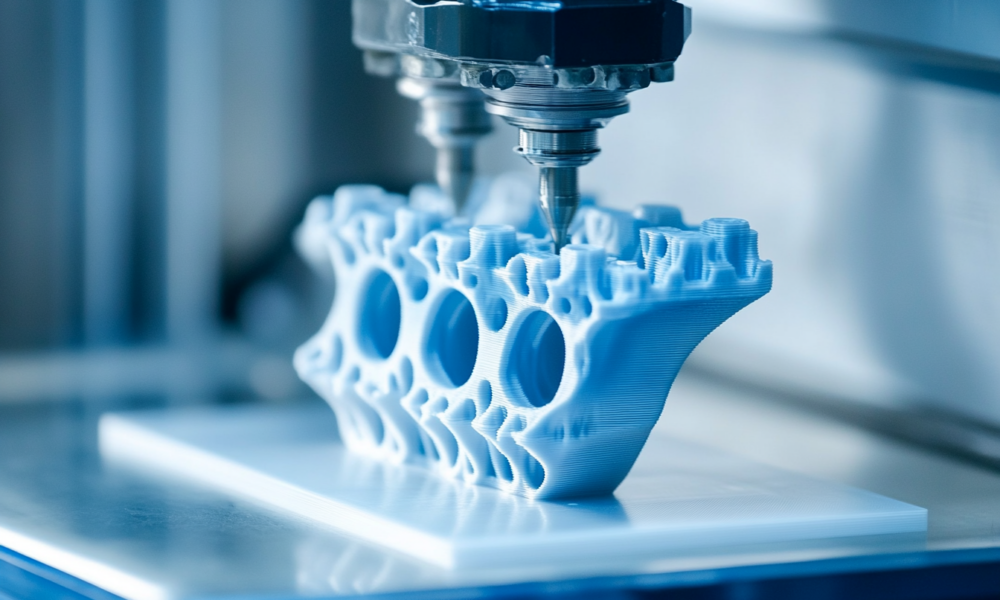

With its ability to print complex geometries and lightweight structures, 3D printing allows companies to rapidly prototype products, facilitating faster iterations and more efficient product development. The integration of these services into manufacturing provides significant cost and time savings while opening new avenues for design that were previously unattainable.

By understanding the diverse applications and benefits of 3D printing services, businesses can make informed decisions that enhance their operational efficiency and product offerings. From startups to established enterprises, the impact of custom parts and innovative designs can shape the future of production.

Understanding 3D Printing Technology

3D printing technology encompasses various processes and materials that create objects layer by layer. It is utilized for producing prototypes and end-use parts across multiple industries. The following subtopics detail the core processes and materials used in 3D printing.

Core 3D Printing Processes

Several key processes define 3D printing technology. Fused Deposition Modeling (FDM) is one of the most common methods, where thermoplastic materials are extruded through a heated nozzle.

Stereolithography (SLA) uses ultraviolet light to cure resin into solid structures, providing high precision and surface finish, making it ideal for intricate prototypes.

Selective Laser Sintering (SLS) employs a laser to sinter powdered material, bonding it together to create strong parts from materials like nylon or metal.

Other notable methods include Multi Jet Fusion, which layers and fuses material in a single pass, and Binder Jetting, which bonds powder particles with a liquid binding agent. Direct Metal Laser Sintering (DMLS) focuses on producing metal parts, offering high-strength components for industrial applications.

Materials Used in 3D Printing

The choice of materials significantly influences the print’s functionality and application. Common 3D printing materials include PLA and ABS, which are popular thermoplastics for prototyping.

Nylon is widely used for its robustness and flexibility, making it suitable for functional parts. Resin is the preferred material for SLA processes, offering superior detail and finish.

Metals, such as stainless steel and titanium, are used in DMLS for high-performance applications in aerospace and medical fields.

Other materials like polycarbonate, TPU, and PETG are also available, catering to various needs, such as impact resistance and flexibility. The selection of materials impacts both surface finish and mechanical properties, vital for applications in diverse industries.

Tips for Choosing the Right 3D Printing Company

When selecting a 3D printing company, consider the following factors:

- Technology and Materials: Check the types of printing technologies offered. Look for options like FDM, SLA, and SLS. Verify the range of materials available, such as plastics, metals, and ceramics.

- Quality and Precision: Evaluate the company’s quality assurance processes. Request samples of their previous work to assess accuracy and finish.

- Experience and Expertise: Consider the company’s track record in the industry. A company with significant experience may better understand various project requirements.

- Customer Service: Good communication is crucial. Assess responsiveness to inquiries and willingness to assist throughout the project.

- Turnaround Time: Ask about the estimated timeframes for production. Ensure they can meet your deadlines without compromising quality.

- Price and Transparency: Compare quotes from several companies. Look for transparency in pricing to avoid hidden fees.

- Reviews and Recommendations: Research customer reviews and case studies. Positive feedback can provide insight into the company’s reliability and service quality.

Choosing the right 3D printing company requires careful consideration of these aspects to ensure a successful partnership.